Why Rotam is Winning

Rotam CEO James Bristow

Amid Hong Kong’s skyscraper city, Rotam CEO James Bristow and part of his team make time to talk to FCI at their new corporate headquarters in Chai Wan, a largely residential district on reclaimed land that began a drastic redevelopment in late 1970s. Cranes still dot the skyline where low-rise residential neighborhoods are razed in favor of high-rise apartment buildings and offices to accommodate the district’s evolution from a rural fishing village to today’s home of multinational corporations.

Like its surroundings, Rotam (publicly listed in Taiwan: 4141) relishes in strategic evolution that stems from long-term development plans, product innovation, partnerships and direct market development.

“We do nothing without a plan that is either portfolio-driven or market access-driven,” Bristow says. “Continuity in planning is essential. Without that, we cannot do what we do.”

What Rotam does is grow, and fast. The company has enjoyed double-digit revenue growth in each of the last five years, and its revenues rose 21% last year. Its strong performance is the result of decades of planning and building infrastructure needed to be a strong global brand. The company works on product development cycles as long as 20 years, and that foresight is showing in its dividends.

Rotam’s sales were $353 million in 2014, driven by 31% growth in Latin America and strong sales in China; the two regions account for 75% of the company’s revenue. Its other regional operations are showing strong growth as well. Its NAFTA division grew 36% last year, and its European business grew 20%.

The company’s Southeast Asia, Africa and Middle East businesses are modest compared to the other regions, but they are being fortified as part of a grand plan. The template for growing those regions has already been established and validated by its success in China, Brazil and  other direct-access markets.

other direct-access markets.

Results are not always instantaneous. But as the operational framework is established in each region, Bristow says Rotam will be well-positioned to capitalize on markets as farmers become more demanding of technology and of the solutions delivered by the products they use. In China, for example, Rotam built a sales and marketing network that might have been a bit ahead of its time, but it’s reaping the benefits now.

“We have been established in China for almost 20 years with an added-value marketing approach with technical solutions [with a direct-to-market model for products and education] when only small parts of the market demanded it,” Bristow says. “China was a big challenge for us because we built something that the market was not quite ready for, but we always believed that China would get there. Then the market moved very quickly to demand this, and we were ready.”

The Chinese market continues to grow quickly as farm consolidation becomes more widespread. Farm consolidation became easier under the government’s Twelfth Five-Year Plan (2011-2015). As a result, lead farmers in various regions tend to be more educated, discerning about products and accepting of new technologies. This plays well into the company’s strategy, and there is ample room for growth, according to Prabhakar Kumar, Rotam senior manager of business development.

China is still segmented; of the approximate $6-billion market, about 50% to 60% of the value is in the value chain, Kumar says. The remaining half of China’s market value is in the products that reach the farmer, about 40% of which carries a strong brand and label, and 60% is commodity post-patent AIs, often unlabeled. As farmers’ sophistication increases, so will their product choices.

“In China, our distribution and marketing has a very strong presence, and we have a good understanding of the market,” Kumar says. “We know there is a lot of opportunity for more technical products in China.”

Chairman Mark Lu and Bristow at Rotam’s IPO in April 25, 2012. The company is listed on the Taiwan Stock Exchange. Lu selected China as Rotam’s manufacturing hub in 1991 and also a key market for the company’s then-fledgling crop protection business. It continues to expand its manufacturing in Asia, most recently with its Rotachem facility in Tianjin.

Anatomy of Evolution

Rotam’s core goals are simple, but they are far from easy. The company prides itself on excellence in synthesis, formulation technology and delivery systems, regulatory and registration expertise, intellectual property defense and freedom to operate know-how. It targets products that solve agronomic challenges and develops market access through both partnerships and direct models when needed.

“We consider regulatory excellence, IP excellence and R&D capabilities from process chemistry through to agronomy as necessary as a company,” Bristow says. “If we don’t have all three, then one will let us down and we will not be able to protect the investment we’ve made in other areas. They need to move together or else we are at risk as an organization.”

The company’s foundation was laid by its methomyl business. Rotam Chairman Mark Lu was running the family’s pharmaceutical business when he discovered a proprietary synthesis process for methomyl. He finished his original synthesis plant in 1991 and began distribution in China. Enter Bristow, a UK environmental chemist with regulatory background, who was tasked with developing registrations in key markets outside of China. He began in Latin America, and the company started its deliberate expansion with synthesis as the backbone of the organization.

“You could say that the company was under construction from 1992 to 2006; it was a basic skeleton, and then we started to put muscles to it,” Bristow says.

Today, methomyl is still Rotam’s highest-selling product with about $62 million in global revenues in 2014, up from less than $22 million in 2010. It enjoys about one-third of the global market share with a heavy investment in product stewardship, and it continues to spend as much time and resources on AI synthesis research and product development today as it ever has, by design. The process chemistry is fundamental, Bristow says.

“We have more synthesis chemists than some manufacturing-focused synthesis companies,” he ![]() says “If you don’t work it out on a molecule level, then you won’t work it out at the formulation level, IP or regulatory level. We started that way. We are a process synthesis technology company. We invest in it because we need to be in control of our process chemistry and molecule chemistry. If we don’t do that, then we can’t solve the puzzle for delivery systems.”

says “If you don’t work it out on a molecule level, then you won’t work it out at the formulation level, IP or regulatory level. We started that way. We are a process synthesis technology company. We invest in it because we need to be in control of our process chemistry and molecule chemistry. If we don’t do that, then we can’t solve the puzzle for delivery systems.”

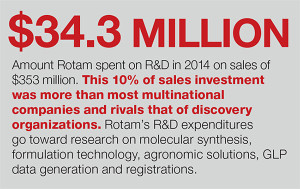

Emphasis on R&D

Rotam synthesizes some of its AIs, but with more than 40 molecules forming its backbone, it is not practical nor economical to produce them all. So its investment in synthesis technology and engineering allows it to implement its R&D with contract manufacturing partners as a way to control the quality of the product. “If we could not do that, then we could not link the elements of synthesis into the elements of formulation development into the elements of product development. It is not enough to be a formulator. Technology cannot evolve quick enough to thrive only in formulations. You need to look at everything that relates around the molecule,” Bristow says.

Rotam’s infrastructure allows it to examine formulations and delivery systems designed for agronomic solutions. Its expansive field research stations that span the globe help it generate data to support its registration and product development, plus they give Rotam the venue to give tours and host farmer celebration days. These events give the company the opportunity to educate local farmers and listen to their challenges with agronomy, which allows them to respond with product solutions.

Data In, Solutions Out

The mountains of data that Rotam has collected through the years of GLP data generation, field trials and other regulatory data generation is a trove of outcomes that the company is now organizing to make available to field reps so they can be more responsive to agronomic demand, a philosophy Bristow calls applied R&D. This applied database will allow field reps to offer heightened service, technical support and product recommendations to distributors, retailers and farmers. It also provides an opportunity to enter end-user feedback into the database to help mold the next generation of crop protection products that meet specific agronomic needs around the world.

“We need to keep evolving,” Bristow says. “There are linkages of understanding in our data; making it accessible to our agronomists and our scientists really takes it to the next level of what our farmers need as technical solutions and especially business solutions. So agronomic solutions are not just agronomy. It is operating as a business and making all of our knowledge management accessible to our applied research and development.”

I f successful, Rotam will have created a data structure capable of predictive modeling that would allow agronomic trends from a particular region to be identified and then extrapolated to similar markets around the world. For example, if an agronomic challenge can be identified in rice in China, then Rotam will be able to predict when Thailand, Indonesia and India might have the same agronomic challenge, thereby allowing the data to direct the next generation of products needed to solve specific agronomic challenges. “We need to look at processes and systems internally in order to deliver more solutions in the market.”

f successful, Rotam will have created a data structure capable of predictive modeling that would allow agronomic trends from a particular region to be identified and then extrapolated to similar markets around the world. For example, if an agronomic challenge can be identified in rice in China, then Rotam will be able to predict when Thailand, Indonesia and India might have the same agronomic challenge, thereby allowing the data to direct the next generation of products needed to solve specific agronomic challenges. “We need to look at processes and systems internally in order to deliver more solutions in the market.”

The idea is forcing a crop protection company to think like a knowledge management company, but the evolution is something Bristow is quite comfortable with. Throughout the company’s history, he points to times where the company has been forced to transform its business, including its supply chain, manufacturing processes, distribution philosophy, partnerships, regional structures and product offerings.

New Seed & Traits Business

Rotam’s newest product evolution is a partnership on seed and traits. Late last year, Rotam struck a deal with U.S,-based Cibus, a gene-editing company that is developing non-transgenic traits through its proprietary Rapid Trait Development System. Cibus’ first product, SU Canola, is resistant to sulfonylurea herbicides, and Rotam will provide two novel SU herbicides as companion chemistries for SU Canola. It was launched in the U.S. market late last year and will be followed with a similar launch in Canada estimated for 2017. Rotam will provide the herbicides for the North American and China markets, as well as distribution support in those markets.

Cibus President and CEO Peter Beetham says Rotam is a good partner for this technology: “Rotam provides fully integrated manufacturing, industry-leading formulation, high quality standards, registration and technical support for a broad product offering that will appeal to farmers across North America and China … Rotam is the foremost crop protection company in China, so it was a natural step to work with Rotam on bringing a new non-transgenic canola solution to the United States, and soon, Canada and other global markets.”

The introduction of this product comes alongside a major global boost in demand for canola, which has been embraced as a healthy alternative for cooking oils and as a valuable biofuel feedstock, Beetham says. The technology could proliferate in markets where transgenic crops struggle to be accepted, notably Europe. However it is unclear whether those markets will accept a trait developed through mutagenesis like SU Canola.

Regardless of the regulatory hurdles, Rotam is poised to enter a new segment with strong potential on the strength of the infrastructure it has worked to lay for its crop protection business. Its direct-market access of many hard-to-reach regions like China could make it a preferred carrier of emerging technologies on many fronts because it understands the needs for growers.

“SU Canola is a good start for us because our strength in herbicides is in the SU portfolio of products, and we need to evolve to have the conversations in agronomy about seed technology and biologicals and other new technologies,” Bristow says. “It is a partnership of development on both on the trait side as well as the chemical side. It is another example of pushing the envelope. We need to identify good partners, and that is a challenge and strength of the organization. It is more than sales; it requires infrastructure, investment and a commitment to the market and farmers’ livelihoods.”

Key Developments in 2014

LATAM: Launched fipronil with proprietary IP position in Brazil; acquired strategic product registrations in Chile.

USA: Launched dicamba, clethodim, and emamectin for tree injection.

EU: Expanded sulfonylurea portfolio and launched dicamba SG.

India: Opened manufacturing plant and process chemistry lab in Udaipur, Rajasthan; Identified as a growth market and working toward formal sales and marketing infrastructure.

Asia: Expanded into new markets; developed direct distribution structure in Indonesia, opened Vietnam office; secured exclusive distribution of Isagro Italy portfolio in China, Taiwan & Indonesia.

China: Opened Rotachem formulation plant in Tianjin, North China that will bolster in-house current formulation capacity by three times when all phases are complete.

R&D: Extended scope of China-based GLP labs with addition of ecotox and genotox capabilities.